Our Products

HYDRAULIC CYLINDERS

|

HYDRAULIC POWER PACK UNIT |

FRL UNITS HONED PIPES HARDCHROME PLATTED SHAFT PISTON ROD ASSEMBLY |

IN-LINE HYDRAULIC VALVE PNEUMATIC CYLINDERS PNEUMATIC CONTROL VALVE |

We are manufacturing and exporting exclusive hydraulic equipment and pneumatic equipment that find usage in various engineering industries. We are also engaged in offering hydraulic cylinders, and hydraulic controls & accessories for our clients based in the domestic & overseas markets. All our equipment is stringently tested at several parameters to ascertain its high performance, strength and durability. Apart from this, we also can custom design our products in accordance with the specifications of the clients.

Our product range includes High Pressure Cylinders For Steel Plant, Hydraulic Power Pack Machine, Honed Tube, Ancillary Valves, Super Mill Duty Hydraulic Cylinder, Poppet Type Solenoid Valve etc.

The wide array includes the following:

Our product range includes High Pressure Cylinders For Steel Plant, Hydraulic Power Pack Machine, Honed Tube, Ancillary Valves, Super Mill Duty Hydraulic Cylinder, Poppet Type Solenoid Valve etc.

The wide array includes the following:

|

We are highly specialized in fabricating hydraulic cylinders which are at par with international standards. These cylinders have high functionality and are available in different capacities. Also, these are manufactured in compliance with industrial norms and standards and customized as per clients’ specifications. Our gamut consists of industrial hydraulic cylinder, ISO series hydraulic cylinder, high pressure hydraulic cylinder, Hydraulic Cylinder for construction and earth moving machinery and heavy duty hydraulic cylinder. Range : From Bore Dia 40mm to 320mm x stroke length 4750mm. |

|

This are ISO 6020/2 series hydraulic cylinders. They are 1 to 1 replaceable to any ISO series cylinder. They are rated for 160 bar design pressure and upto 210 bar test pressure. Range : From bore dia 40mm to 250mm and stroke length max. upto 5580mm. We can give 18 types of mountings as per the international standard. |

|

Mill Duty, Welded construction design hydraulic cylinders are specially designed for the sturdy machines of steel plant, rolling mills, continuous casting machines and all other heavy engineering application. Range : From bore dia 40mm to 450mm stroke length upto 6850mm (upto 250mm boar), and 3500mm stroke for the higher bore size (upto 450mm). Pressure Range : Min. 50 bar to 210 bar and max. upto 350 bar. These cylinders are offered with all standard as well as special mountings and cylinders can be offered with rod end fork fitted with spherical bearing. |

| We are providing our durable industrial hydraulic cylinders which are available in 15 different mounting styles. These can be mounted as per the request of the clients. These can perform smoothly with working pressure of 130 bar and high pressure of 300 bar. Our industrial hydraulic cylinders are offered with stroke length up to 3000 mm. Features: – Tie Rods Design – Bore 40 mm to 400 mm, Bigger bore on request – Stroke length up to 3000 mm, longer stroke on request – W. pressure 130 bar. Higher pressure up to 300 bar on request – 15 different mounting styles. Special mounting on request – Cylinders could also be offered with JIC & cetop standards. |

|

|

Our firm is engaged in exporting a large variety of Hydraulic Cylinder For Offshore Equipment. 280 mm Hydraulic Cylinder For Offshore Equipment are made for 1200 Ton Jack Up Barge applications. Precisely engineered these cylinders are offered with the customization facility that enables the clients to pick their desired option. These cylinders are equipped with the advanced technologies and optimum quality raw materials. |

|

We are engaged in offering good quality Hydraulic cylinders for Curing Press. The Hydraulic Curing Press has working pressure of 250 bars.The dimensions of its cylinder are 390X380X750. It weighs 350 tons. It is used as a solid type curing press. The curing bladders are made of special heat resistant compounds. It is made of tough quality raw materials. It is energy efficient and fully computerized. It is well appreciated by our customers. |

|

Marine hydraulic cylinders in action The marine environment is by far the most arduous for hydraulic equipment with many and varied conditions that combine to increase the likelihood of premature failure. It is very important therefore to design hydraulic cylinders with these particular environmental conditions very much in mind, if they are to perform at or above expectations. Corrosion is the largest single contributor to premature failure and we therefore take many precautions during design and manufacture to ensure cylinder life is not compromised. Common Applications – Steering and Rudder Control – Ride Fins – Hoistable Decks & Ramps – Cranes & Davits – Bow & Stern Doors – Personnel Lifts – Goods Lifts – Ammunition Lifts – Clam Shell Systems – Watertight Systems – Deck Hatches – Locking Dogs – Heave Compensators, active & passive – Riser Tensioners – Mooring Tensioners We design cylinders for all types of marine environments including those experienced in applications for vessels such as; Naval vessels. Offshore rigs and support vessels. Subsea vessels. Passenger vessels such as Ocean Liners and Fast Ferries. Commercial vessels such as Bulk Carriers, Car Carriers and Tankers. Ship Mounted or Dockside Cranes. Megayachts and other luxury vessels. |

| The gamut of heavy duty hydraulic cylinders catered by us is of excellent quality and extensively used in various application areas. These cylinders are available in diameter of 40mm to 450mm with stroke length of up to 5580mm. Apart from this; these heavy duty hydraulic cylinders are available with square and round end covers and in 12 different types of mountings. Applications: – Mining Equipment – Mobile Machinery – Marine Equipment – Defense Equipment – Steel Mill Equipment – Power Projects Equipment – Forge and Foundry Equipment. |

|

|

These are very very special purpose mill duty, welded construction design hydraulic cylinders designed for the sponge iron plant. Here the bottom cover & clevies is made from single piece MS Profile. Cylinder barel is made from burnished tube. Rod end fork is machined from forged steel. rear clevies & rod end fork is fitted with ge100es spherical bearing. Cylinder can give force of 42 tons 250 bar pressure. Here port sizes are increased & made upto 2″ b. S. P. So that total travel of 300mm. Can be completed within 15 secs. Only. All the seals are fitted with frictionless turcon material glyde ring & slyde ring. Rod end guide is provided with additional phosphour bronze bush. Piston rod is induction harden. |

|

Fluid Power make mill duty cylinders are designed to meet the tough demands of primary metals customers for cylinders used on arc furnaces, slab casters, rolling mills, coating lines, and other applications. Available in standard bore sizes from 50 mm (2.0 in.) to 400 mm (16.0″in.) with strokes up to 4.5 m (177″ in.), these robust cylinders are engineered to survive in these, and similar, extremely demanding applications. Fluid Power make mill duty cylinders are also available in custom configurations offering larger bore sizes, longer strokes, and higher operating pressures. |

|

These are heavy Duty Hydraulic cylinders made for the gate Opening of L&T. It’s size is Bore dia 250mm x Rod dia 160mm x Stroke 1500mm. It can develop a thrust of 70 tons 240 bar pressure. |

|

We are expert in manufacturing and supplying high pressure hydraulic cylinders which are widely used for various applications. Fluid Power Cylinders are spiritually used in the Continuous casting Machinery of 4/7 mtrs and 6/11 mtrs,2,3,4 & 6 strands. Apart from this, we have specially developed mill duty, welded construction design high pressure cylinders for different applications such as; straightener, pusher, dummy bar receiver, RDBG. Also, these can work under high pressure of 160 bar and tested for 240 bar pressure. Besides, we have specially developed cylinders for steel plant equipment such as; 4 HI MILL, 6 HI MILL, 20 HI MILL, Wire Rod Mill, CRM, HRM. These cylinders are available with leather bellows with different types of mountings offered for ISO cylinders. Applications: • Garbage compactor • Steel plant equipment • Earth moving machinery • Continuous Casting Machinery |

|

This is are special purpose hydraulic cylinders made of SS 304 & 316 grade barel. ID Duely honned. it is designed as per the iso 6020/2 series specification. Sizes are available from bore dia 63mm upto 400mm & stroke length upto 3500mm. Long. All types of mountings are available. |

|

We are offering precision engineered hydraulic cylinders which are in compliance with ISO 6020/2 Series. These cylinders are offered with Vidyun brand and cater to the requirements of various industrial applications. Also, these hydraulic cylinders are available in ten mounting styles with pressure rating of about 160 bar. Our hydraulic cylinders are offered with bore size of 40 mm up to 200 mm and rod size of 18mm up to 140mm. Features: – Ten mounting styles – Pressure rating 160 bar – Numerous option features – Bore size 40mm up to 200 mm – Rod size 18mm up to 140mm – Superior quality standard seals – Suitable seals for various media – Rod and mounting selection guide – Square Headed Tie Rod Construction – Option of three ram size per bore size Mounting interchangeability with any ISO cylinders Features of vidyun brand hydraulic cylinders: – Ram supporting bush of phosphor bronze material. – Rod seals are either bushak, shamben or superior quality polyurethene seals. – Piston rods are made from en-8 steel, ground & hard chrome plated to impart good service life to gland seals. – Gland bearing is either slyderings bushak, shamben or graded cast iron, which is self lubricating. – Piston seals either of ‘pu’ material `u cup’ with equal lip type or b, s type or d-a-s compact double acting type. These are composite seals with bronze filled ptfe wear rings on either sides & elastomeric sealing element in the centre. – Cylinder barrels are made of cold drawn seamless material of msl make. I.d. duly honed. Hard chrome plating under special application is done. Product Code: ISO-Series-Hydraulic-Cylinder |

|

It is mill duty, welded construction design hydraulic cylinders used for the car application in steel plants. These cylinder has a capacity of 70 tons. This cylinder is made as an Import substitution for Germany make cylinder of one of the leading steel plant in India. Size of the cylinder: Bore dia 250mm x rod dia 140mm x stroke 925mm. Mounting style: Intermediate trunion mounting. Working pressure: 210 bar. |

| We have specialized ourselves in the manufacturing of all types of honed tubes for the continuous casting machines. I. E. 4/7 mtrs. 2 ,3 & 4 strands ccm & also 6/11 mtrs. 2,3 & 4 strands ccm. Above photograph is of a cross transfer pusher cylinders manufactured for 6/11 mtrs. 4 strand ccm. It’s specification is as under. – Size : Bore dia 160mm x rod dia 110mm x stroke 510mm. – Type : Double acting with fixed cushioned at both ends. – Mounting : Cap end clevies mounting. Along with rod end fork. – Ports ” 1. 1/4″ b. S. P. – Working pressure : 210 bar – Test pressure : 240 bar – Temp : upto 80 degree cen. – Seals : Bushak, Shamben. – Payment Terms: L/C (Letter of Credit) – Production Capacity: 120 nos PER MONTH |

|

|

We have successfully designed & manufacture mill duty hydraulic cylinder especially for shearing machine. This cylinder is suitable for the working pressure upto 250 bar & temperature upto 300°C Size : Bore dia 350mm x rod 200mm x stroke 175mm. Working pressure : Suitable for working Pressure of 160 bar. |

|

This cylinder is rated for max. 15kg pressure. Fitted with high temp. viton seals & Induction harden shaft. Size : Bore Dia 5″in x Rod Dia 45mm x Stroke 900 to 1250mm (Varies from customer to customer). |

|

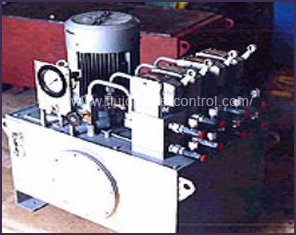

We are providing hydraulic power pack unit which exhaustively caters to the requirements of various industrial sectors. These power packs have flexible manifold design and are able to offer different levels of response, product quality and service. Owing to the quality standard, the gamut is highly demanded in domestic as well as in international market. Applications: • Compact space • Flexible manifold design • Used in Mobile and Industrial applications • Able to provide high levels of response, product quality and service • Designed and manufactured in-house using the latest design and manufacturing technology. Product Code : Hydraulic-Powerpack-Unit |

| The gamut of 5- station hydraulic cylinder power pack offered by us caters to the specific requirements of the clients. These hydraulic power pack are extensively used for special purposes and designed for steel plant equipment, pipe mills. In these hydraulic power packs, cylinders are mounted in the basement or far off from the machine. In these power packs, 20 odd cylinders can be easily operated from the same power pack at 210 bar continuous pressure. Product Code : 5-Station-Hydraulic-Powerpack |

|

|

Keeping in sync with time, we are able to offer an unparalleled range of FRL Units. The offered range of FRL units is made utilizing optimum grade raw material and modern machinery in strict conformation with the industry laid standards. Along with this, the offered range is available in different customized specifications and forms in accordance with the diverse requirements of clients. |

|

The wide assortment of mini series frl unit is a highly compact package which caters to the needs of various application areas. These units are offered with flow up to 20scfm and having size of about 1/4″ bsp and 3/8″ bsp. We stringently test our products on several parameters to ensure durability and high performance. |

|

The wide array of flexi series FRL unit is fabricated with the help of our engineers and designers using sophisticated technologies. These units are known for impeccable quality and are available in different sizes of 1/4”, 3/8″, 1/2″ and 3/4″ BSP. These are based on complete modularity concept one body size with 4 different pipe sizes. Features: • Ease of Service • Unmatched quality performance • Less than one minutes downtime • Available in sizes of 1/4″ , 3/8″ , 1/2″ and 3/4″ BSP • Total modularity concept one body size – 4 different pipe sizes • Less Inventory plus simplified specification ordering and service |

|

We are providing jumbo series FRL unit which is available with modular designs, pressure switches and lubricator units. Also, these units are provided with various types of valves such as; manually operated ON / OFF valve, solenoid operated ON / OFF valve and air pilot operated ON / OFF valve. Also, we are offering customized solutions as per the requirements of the clients. Features: • Modular design • Pressure Switch • Lubricator units • Air distributor units • Filter-regulator units • Safety start up valve • Manually operated ON / OFF valve • Solenoid operated ON / OFF valve • Air pilot operated ON / OFF valve • Available in sizes of 1/2″ BSP to 2″ BSP • Filter units with manual/ automatic condensate drain |

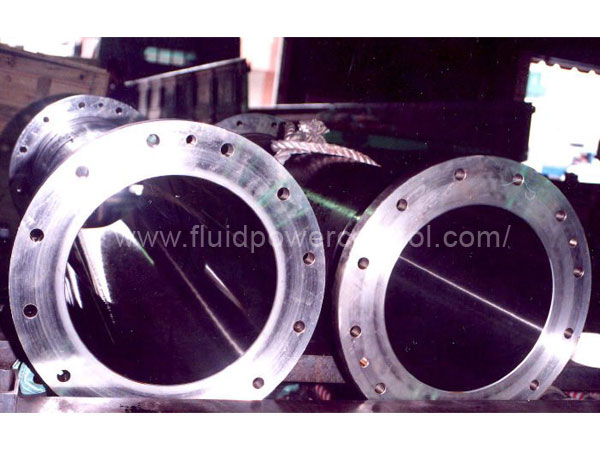

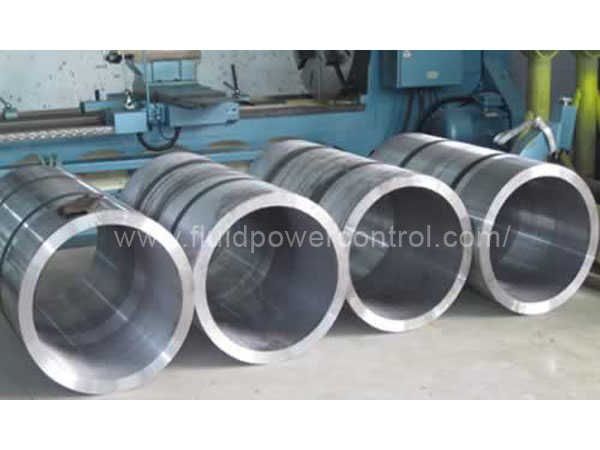

| Horned pipes are used for cylinder and pneumatic purpose with inside mirror finished honing. These are provided in size as per customer requirements. Material : ST-52 grade, cold drawn seamless barrel. We have in house facilities of honing. We can give all popular sizes from 40mm. ID To 200mm. ID & standard length upto 3000mm. Above on request & specific order. Also, we make honed tubes for the mill duty welded construction design hydraulic cylinders for our own use & also for the selling purpose, where the flanges are welded at both ends of pipe. They are custom made & as per the drg. Of clients. Only. |

|

|

We make Honed Tubes where flanges are welded, which provides extra strength to the hydraulic cylinder. Such type of Construction is preffered mainly for all the heavy engineering industrial application. Flanges are threaded & then welded & then machined which ensures that it is thro’. |

|

As a cylinder manufacturer we keep good quantity of HCP Shaft readily available. All standard sizes from 12mm dia to 63mm dia in length of 3.5 to 4 mtrs are easily available. Sizes above this are made against order. Material : EN-8 (D), Centreless, Ground & Hardchrome platted. Plating thickness 25 microns & above on request. Range : From 12mm dia to 210mm x 7000mm. |

|

We not only provide shafts but also give complete piston rod assembly duely fitted with locknut, seals, etc. Readymade assemblies ensures lots of time saving during the critical shut down. They are made generally as per customer’s drawing. They are fitted with variety of seals i.e. Pu, Turcon Seals etc. |

|

Our gamut of hydraulic valves, hydraulic pressure valves is fabricated with best grade of cold drawn steel bar with proper internal working parts. These cylinders are well recognized for high performance and durability. The line bodies, hydraulic integrated circuit blocks and special bodies are available with high strength, wrought aluminum bar and mild steel or stainless steel. We use steel bodies for pressures above 210 bars. Features: • NPT threaded on request • Valves up to 10000 PSI pressure • Recommended Fluid is ENCLO – 68 • Sizes offered from 1/4″ BSP to 2″ BSP. |

| Our encompassing gamut of heavy duty pneumatic cylinder is widely used for heavy duty all- steel constructions. These pneumatic cylinders are available with 8 additional mounting styles in special designs to suit the requirements of the clients. All our cylinders are fabricated with the help of our technicians and are in compliance with ISO-6430. Features: – Heavy duty all-steel construction – 8 additional popular mounting styles – Special designs as per customer requirements – 25mm to 350mm Bore & Stoke upto 4320mm. Cylinders are offered with 15 mounting arrangements conforming to ISO-6430. |

|

|

We are offering light duty pneumatic cylinders which are available in different piston diameter ranging from 32 to 100 mm. Also, these cylinders are available with standard stroke of 25-500 mm and maximum stroke of 1000-1500 mm. Also, these cylinders can be modified as per client specifications and the detail descriptions of our products are mentioned below. Technical Specifications:

|

||||||||||||||||||||||||||||||||||||

|

We are catering an exclusive gamut of pneumatic tandem cylinders which are available with 3 pistons and consist of two or more cylinders which are arranged one behind the other as a single unit. These tandem cylinders are widely used in various applications which have two or more independent systems like power operated flight control systems in naval aircraft. Features: Light in weight Totally Customized Compact one-way lock mechanism for tight spaces. |

|

Our range of 4 way valves is available in wide variety of specifications as per the requirements of clients and area of application. It has the ability to bear temperature up to 80o C. fabricated making use of the best quality brass and aluminum to ensure high durability and quality. Our range has the following features: FP 400 – Type: FP 400/4 way 5 position single and double solenoid valves direction control for double acting cylinder. – Size: ¼” BSP / NPT. – Med.: Air, Water, Light-Oil. – Port size: 1.5 mm., 2 mm. – OP. pressure: 0.5 to 10 Kg. / Cm2 – Body material: Forged Brass. – Fluid temperature:80oC Max. FSP 400 – Type: FSP 400/4 way 5 port 2 position single solenoid & 3 position double solenoid valves full port for direction control of double acting cylinders. – Size: ¼” BSP / NPT. – Med.: Air – Port size: 6 mm. – OP. pressure: 1 to 15 Kg. / Cm2. – Body material: Aluminum / Brass. – Fluid temperature: 80oC Max. FPA 400 – Type: FPA 400/4 way 5 port 2 position single and double solenoid valves full port for high volume actuators and cylinders. – Size: ¼” to 3/8” BSP / NPT. – Med.: Air, Water, LD Oil. – Port size: 6 mm. – OP. pressure: 1 to 15 Kg./Cm2 – Body material: Brass and Hard Anodized Aluminum. – Fluid temperature: 80oC Max. FPA 410 – Type: FPA 410 / 4 way 4 port 2 position & 3 position high capacity solenoid valves. – Size: 3/8” to ½” BSP / NPT. – Med.: Air, Water, l.d. Oil. – Port size: 12 mm. – Op. Pressure: 1 to 15 Kg./Cm2. – Body material: Bronze – Fluid temperature: 80oC Max. * 3/4 ” to 1.1/2 ” on request. |

|

Our precision engineered hand lever and push-pull valves are available in different types such as; 3-ways and 4-way hand lever, 2-positions, 3-positions, (PRN, PHN, and PAN). These valves are offered in various sizes like 1/4″ BSP, 1/2″ BSP, 3/4″ BSP with powder coated aluminium body. Also, these valves have high working pressure of about 0 to 10 kg /cm2 with actuator of hand lever or push-pull type. Apart from this, we are also offering in other models such as; foot pedal valve, roller valve, disc rotary valve, pilot-pilot valve. Technical Specifications: • Types: 3 ways and 4 way hand lever, 2-positions, 3-position, (PRN, PHN, PAN) • Sizes: 1/4″ BSP, 1/2″ BSP, 3/4″ BSP • Pressure: 0 to 10 kg /cm2 • Actuator: Hand lever or push-pull • Media: Air filtered and lubricated • Body: Powder coated aluminium body • Other models: Foot pedal valve, roller valve, disc rotary valve, pilot-pilot valve |

|

We are catering direct acting solenoid valve which are available with optimum sizes of 1/8″ BSP and 1/4″ BSP. These valves are offered in different types such as, 2 or 3 ports direct acting solenoid valves with brass & powder coated aluminum body. These solenoid valves perform smoothly in any medium whether it is air, water or non corrosive liquids and gases. Technical Specifications: • Manual over-ride: optional • Pressure: 0 to 10 kg / cm. • Size: 1/8″ BSP & 1/4″ BSP • Orifice: 1.50mm, 2.5mm. standard, oilier sizes on request • Media: Air, water and non corrosive liquids and gases • Types: 2 ports & 3 ports direct acting solenoid valves, 2 way & 3 way normally closed/ normally open • Body Material: Powder Coated aluminum body, Brass and stainless steel against specific orders • Solenoid Data: Epoxy moulded water proof continuous duty coils, 6 to 230 VAC, 6 to 220 VDC. 6.5 watts. Optional terminal junction box can be provided on all coils. |

|

The gamut of poppet type solenoid valves catered by us is of top-notch quality and is available in various sizes such as; 1/4″ BSP, 1/2″ BSP. Also, these valves perform high on pressure of up to 2 to 10kg /cm2 and with hard anodized aluminum body. Also, these solenoid valves perform flawlessly in any air-filtered and lubricated medium. Technical Specifications: • Sizes: 1/4″ BSP, 1/2″ BSP • Pressure: 2 to 10kg /cm2 • Media: Air-filtered and lubricated • Types: 3 port and 4 port poppet valves • Body Material: Hard anodized aluminum body • Orifice: 5.00mm for 1/8″ BSP, 6.5 mm for 1/4″ BSP & 12.50 mm for 1/2″ BSP • Solenoid data: Round type, epoxy moulded, water proof, continuous duty coils, 6 to 230VAC, 6 to 220VDC, 6.5 watts. |

|

We are specialized in fabricating gang control valves which are widely used for automatic and electric actuators. These are sub- base valves and gang manifold valves in such forms which offer base mounting, for repairing or servicing. Owing to the quality standard, these valves are repetitively demanded in domestic as well as in international marketplace. |

|

We are fabricating sub base valve and gang manifold which is available in series like “S” & “D” and “P”, 2-way, 3-way, and 4-way valves with sub-base versions. Our products can be gang assembled and thus enable conversion of sophisticated into neat, compact and stream lined assemblies. Apart from this, we also provide valuable engineering assistance in transforming customers existing circuits into gang assemblies. Product Code : Sub-Base-Valve-and-Gang-Manifold |

|

The gamut of spool valves is available in different types such as; 3 ways and 4 way spool valves, 2 positions and 3 positions. These valves are offered in various sizes like 1/8″ BSP, 1/4″ BSP, 1/2″ BSP & 3/4″B.S.P.They are powder coated aluminum body. Also, these valves are available with pressure range of 2.5 to 10 kg / em- for pilot and solenoid valves. Technical Specifications: • Types: 3 way & 4 way spool valves, 2 positions and 3 positions, PHN, PRN, PAN • Sizes: 1/8″ BSP, 1/4″ BSP, 1/2″ BSP, • Pressure: 2.5 to 10 kg / em- for pilot and solenoid valves • Orifice: 5.00 mm for 1/8″ BSP, 6.5 mm for 1/4″ BSP & 12.50 mm for 1/2″ BSP. • Media: Air-fiuered and lubricated • Body Material: Powder coated aluminum body. Brass and stainless steel against specific orders only. • Solenoid data: Epoxy moulded, water proof, continuous rated coils, 6 to 230VAC, 6 to 220VDC, 6.5 watts. |

Years in Business

0

+

Happy Customers / Year

0

+

Employees

0

+

Service country

0

+

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide

Click to Preview Slide